The difference between acoustic emission sensor and vibration sensor

Comparison of Acoustic Emission Sensors and Vibration Sensors

Acoustic emission testing method: A non-destructive testing method that evaluates material performance or structural integrity by receiving and analyzing acoustic emission signals of materials. Acoustic emission (AE) is a stress wave phenomenon in materials caused by crack propagation, plastic deformation or phase The strain caused by the change can be quickly released.

Vibration measurement method: It is a measurement technology that detects vibration changes, converts them into corresponding electrical signals, facilitates display, analysis and processing, and extracts the required useful information.

For these 2 methods, the acoustic emission detection method adopts the acoustic emission sensor, and the vibration measurement method adopts the vibration sensor. Then, we will compare these 2 sensors to help us choose the method for equipment detection.

Let's talk about what the acoustic emission sensor and the vibration sensor have in common. They are both based on the piezoelectric principle, and the vibration signal is converted into an electrical signal through a piezoelectric crystal. It can be used to detect whether the device is good or bad.

Let's talk about the differences between them:

The structure of the sensor is different: the acceleration sensor is a structure of piezoelectric ceramics and mass blocks, while the acoustic sensor is only piezoelectric ceramics.

Different sensitivity: The sensitivity of the acceleration sensor is a fixed value, while the sensitivity of the acoustic emission sensor has no fixed value, but is represented by the response curve. For signals of different frequencies, the sensitivity is different.

The difference between the signal received by the sensor and the output: the acceleration sensor converts the acceleration value into a charge (not a built-in preamplifier), and the output charge is proportional to the acceleration of the vibrating particle. The sensitivity unit is PC\/M\/S2;

The output of the acoustic emission sensor is proportional to the velocity of the vibrating particles, and the sensitivity is MV\/M\/s; in other words, although all the received vibration signals are vibration signals, the physical quantities of the specific received vibration signals are different, resulting in The sensors function differently.

Installation direction: Sound has no direction, vibration has no direction.

Applicable equipment: the sound is more suitable for low-speed variable speed and non-full-cycle occasions, and it is easier to find early fault micro-ripples. Its scope of application is wider than vibration.

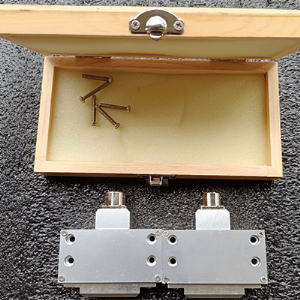

In terms of application: the vibration sensor needs to be fixed with the measured object to form a vibration system. Therefore, the best installation method is to fix the sensor on the measured object with screws. Therefore, the vibration sensor is used to detect the vibration of the entire measured object , can be said to be a "macroscopic phenomenon"; the vibration frequency is generally low, so the vibration sensor is suitable for low frequency bands.

The acoustic emission sensor detects the stress wave generated by the local defect of the material, and is used to detect the vibration generated locally in the material, which can be said to be a "microscopic phenomenon"; therefore, as long as the installation method is close to the sensor, the fixture can also be used. However, due to This kind of stress wave is seriously attenuated when propagating between media, so a coupling agent is usually used between the measured object and the sensor. In addition, there is an air-coupled acoustic emission sensor that can be used without contacting the measured object Detection. The stress wave generated by the internal breaking of materials is a high-frequency vibration. Therefore, the acoustic emission sensor is suitable for high-frequency bands, usually with a boundary of 20kHz.

Application: The sound sensor is sensitive to materials, susceptible to noise interference, and requires high skill and quality of people. It can only be used with a complete system, so the system is very expensive. The vibration sensor is simple and convenient. It is the most widely used in the field of vibration Wide range of sensors.

Previous: acceleration sensor