Frequently Asked Questions about Vibration Sensors

The component modules of the vibration sensor are encapsulated in the housing. During operation, it will be powered by a battery or a vibration generator to form a wireless vibration sensor network node. The network consists of randomly distributed micro-nodes integrating sensors, data processing units and communication modules.

The vibration sensor network system usually includes sensor nodes, sink nodes and management nodes. During the vibration transmission process, there may be problems such as zero output on site. According to the analysis of the vibration sensor manufacturer, the possible reasons for the error of the wireless vibration sensor are as follows: 1. When When the input of the vibration transmitter is zero a, check whether the polarity of the power supply can be reversed B, short-circuit the test terminal, and check the 2-pole tube in the shell. 2. When the vibration transmitter cannot communicate a, check the transmitter Check the power supply voltage on the transmitter b, check the load resistance C, replace the electronic circuit board 3, when the vibration transmitter reads high or low a, check the reading of the vibration variable b, stop the 420mA input to adjust C, replace the electronic circuit board D, check Whether the vibration output is blocked e, check the inspection device F stop the sensor adjustment 4. When the input vibration of the vibration transmitter A does not respond. Check the power supply voltage of the transmitter B. Check the inspection device C. Correct the calibration set value (4 and 20mA point) d. Replace the electronic circuit board 5. When the vibration transmitter reads irregularly A. Check whether the vibration output is blocked B. Check whether the electromotive force interferes with the wireless vibration sensor 6. When the vibration output, the vibration transmitter input does not increase , the input of the vibration transmitter has not changed, and then the input of the vibration transmitter changes suddenly, so the zero position of the vibration transmitter cannot be returned. A. In this case, check whether the vibration is static. After checking the wiring method and power supply , if ok, check sensor zero for input. Maybe just check if the output can be changed. If there is a change, then the sensor is not damaged. If there is no change, the sensor is damaged. First, I am looking to see if it is surface damage or the whole system The results of other links. 7. The input signal of the vibration transmitter is unstable a. The vibration source itself is a stable fluctuating vibration B. The anti-interference ability of the surface or vibration sensor is not strong. The sensor wiring is not firm D. The vibration of the sensor itself Very violent. Defect of the sensor 8. When the pressure transmitter is connected to a power supply, there is no input. The wrong wire is connected (the surface and the sensor should be checked) B. The wire itself is open or short circuited C No power input or power supply does not match D, Surface damage or surface mismatch e, sensor damage

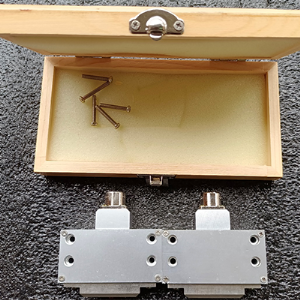

The vibration sensor node is compact in structure and small in size. It consists of a power supply module, an acquisition and processing module and a wireless transceiver module, and is packaged in a polyphenylene sulfide plastic shell. Each channel of the node is equipped with an independent high-precision 120-1000Ω bridge resistance and amplifier The conditioning circuit can be easily and automatically switched by software to select 1\/4 bridge, half bridge, and full bridge measurement methods, and is compatible with various types of bridge sensors, such as strain, load, torque, displacement, acceleration, pressure, temperature, etc. The node supports both 2-wire and 3-wire input modes. The bridge is automatically balanced and can also be stored in the built-in 2m data memory of the node. The effective outdoor communication distance can reach 300 meters. It can continuously measure for more than 10 hours.

Application Technology of Vibration Sensor

1. Low power consumption design

All modules are designed with ultra-low power consumption. The entire sensor node has very low current consumption. It can work for several years with 2 ordinary dry batteries, which greatly prolongs the maintenance cycle. Therefore, the micro-vibration generator can also use the piezoelectric principle to collect The weak vibration energy generated by the structure is converted into electrical energy and powers the sensor. In order to reduce power consumption, the sensor chooses ultra-low power consumption products, and the sensor turns off the power or puts it in sleep mode when it is not collecting. It is truly maintenance-free .

2. Time synchronization

Lz260 wireless sensor is a TDMA transmission protocol based on time synchronization and fixed routing table, which can realize "simultaneous" sleep and "simultaneous" wake-up, and is suitable for online monitoring and detection of wireless sensor industrial automation.

Wake-Up Mode for Wireless Vibration Sensors

In a wireless sensor network, nodes wake up in the following ways:

(1) Full wake-up mode: In this mode, all nodes in the wireless sensor network wake up at the same time to detect and track targets in the network. Although high tracking accuracy can be obtained in this mode, it is a huge at the cost of network energy consumption.

(2) Random wake-up mode: In this mode, the nodes in the wireless sensor network wake up randomly with a given wake-up probability P.

(3) The wake-up mode is selected by the prediction mechanism: in this mode, the nodes in the wireless sensor network selectively wake up those nodes that benefit a lot in terms of tracking accuracy according to the needs of the tracking task, and predict the next The status of the target at a moment, and wake up the node.

(4) Task cycle wake-up mode: In this mode, the nodes in the wireless sensor network are periodically in the wake-up state. Nodes in this working mode can coexist with nodes in other working modes and assist nodes in other working modes .

Previous: No Information