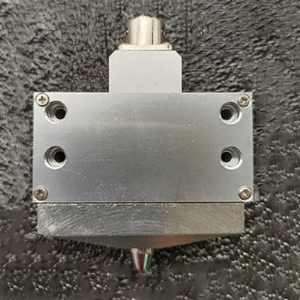

acceleration sensor

Capacitive vibration sensors obtain variable capacitance by changing the gap or common area, and then measure the capacitance to obtain mechanical vibration parameters. Capacitive vibration sensors can be divided into variable gap type and variable common area type. The former can be used to measure linear vibration displacement , the latter can be used to measure the angular displacement of torsional vibration.

Capacitive accelerometers work similarly to piezoresistive accelerometers in that they measure changes in a bridge circuit. However, instead of resistance, they measure changes in capacitance. The sensing element consists of 2 parallel plate capacitors , operate in differential mode. They rely on a carrier demodulation circuit or its equivalent to produce an electrical output proportional to acceleration. There are several types of capacitive elements. One type consists of a metal sensing diaphragm and an aluminum oxide capacitor plate. 2 fixed plates sandwich the diaphragm to form 2 capacitors. Each has a fixed plate and 2 normal diaphragms as movable plates.

Capacitive accelerometer vibration sensors experience a shift in capacitance caused by a change in distance between electrodes when exposed to acceleration. This change is due to the movement of the bend, which also acts as an electrode.

When the sensor is placed in the earth's gravitational field or accelerated by vibrations on the test structure, the force experienced by the spring mass is proportional to the mass of the spring mass and is determined by F=ma. Therefore, the spring mass deflects linearly according to the spring equation:

This deflection causes a change in the distance between the electrode and the spring mass. These changes have a direct effect on each relative capacitor gap according to:

Capacitive accelerometers require a built-in circuit that has 2 functions: it allows changes in capacitance to help measure static and dynamic events, and it converts the changes into a voltage signal compatible with the readout instrument.

Silicon micromachining techniques can be used to fabricate capacitive, piezoelectric, and piezoresistive accelerometers. The single-crystal nature of silicon, the elimination of mechanical joints, and the chemical treatment of mechanical stops yield sensors with high range capability. Using gas instead of silicone oil as the damping medium can extend the damping characteristics over a wider temperature range. The central mass of a series of grooves and holes extrudes the gas, and its thermal viscosity changes little relative to that of silicone oil through the mass displacement structure. Capacitance Type MEMS accelerometers can measure accelerations from <2 g="" to="" hundreds="" of="" g,="" at="" frequencies="" up="" to="" 1="" khz,="" and="" can="" withstand="" shock="" levels="" of="" 5000="" g="" or="" more.="" most="" of="" them="" use="" electronics="" that="" inject="" signals="" into="" components,="" to="" bridge="" and="" condition="" the="" signal.="" the="" negatives="" of="" these="" accelerometers="" are="" limited="" high="" frequency="" range,="" relatively="" large="" phase="" shift,="" and="" higher="" background="" noise="" than="" comparable="" piezoelectric="">

A capacitive acceleration vibration sensor usually includes two capacitors, a modulation circuit, a gain and a filter.

Servo (Force Balance) Acceleration Vibration Sensor

Acceleration-vibration sensors described so far can be classified as "open-loop" devices. Seismic mass deflections proportional to acceleration are directly measured using piezoelectric, piezoresistive, or variable capacitance techniques. Due to the non-linearity of deflection, the mass displacement associated are some small but finite errors. Servo accelerometers are a "closed loop" device. They keep the internal deflection of the proof mass within very small limits. The mass is kept in a "balanced" mode, which virtually eliminates nonlinearity induced Error. Bending systems can be linear or drooping. An electromagnetic force proportional to the feedback current keeps the mass at zero. When an object tries to move, a capacitive sensor detects its movement.

Servo accelerometers are more expensive open loop. They typically have a range of less than 50 grams and are accurate enough to be used in guidance and navigation systems. For navigation, a 3-axis servo accelerometer is often combined with a 3-axis rate gyroscope in a thermally stabilized In a mechanically isolated component, as an inertial measurement unit (IMU). The IMU can determine the 6 degrees of freedom needed for space navigation. They measure at DC (0 Hz) and are generally not popular because of their high frequency response. However, It is usually used in the low frequency field.

Advantage

1) Good temperature stability

The capacitance value of capacitive sensors is generally independent of the electrode material, which is conducive to the selection of materials with low temperature coefficients. Because of its small calorific value, it has little effect on stability. Resistive sensors have copper loss, and are prone to zero-point drift due to heating.

2) Simple structure

The capacitive sensor has a simple structure, is easy to manufacture, and has high precision. It can be very small to achieve some special measurements; it can work in harsh environments such as high temperature, strong radiation, and strong magnetic field, and can withstand large temperature changes, high pressure, high pressure, etc. Shock, overload, etc.; it can measure ultra-high temperature and low pressure difference, and can also measure magnetic work.

3) Non-contact measurement and high sensitivity

It can measure the vibration or eccentricity of the rotating shaft and the radial clearance of the small ball bearing without contact. When using non-contact measurement, the capacitive sensor has an average effect, which can reduce the influence of the surface roughness of the workpiece on the measurement.

In addition to the above advantages, capacitive sensors can also measure very low pressure, force and small acceleration and displacement, because the electrostatic attraction force between the charged plates is very small, and the required input force and energy are very small. It can be Very sensitive, high-resolution, and can detect the range of 0.01μM or less. Due to its small dielectric loss (such as air), the zero residue generated when the differential structure is connected to the bridge is very small, so the circuit allows The magnification is enlarged, so the instrument has high sensitivity.