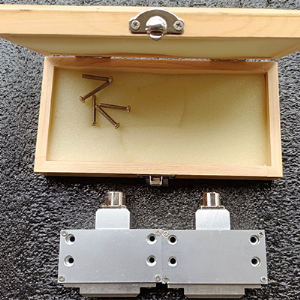

Bearing vibration measuring instrument

The bearing vibration (velocity) measuring instrument is a special instrument for measuring the vibration velocity of deep groove ball bearings, angular contact ball bearings and tapered roller bearings. The high-precision air bearing spindle is used as the measurement reference, and the basic vibration of the instrument is low. Advanced computer It is suitable for data collection and data processing. It is suitable for bearing vibration detection by bearing manufacturers, bearing acceptance by bearing application and commodity inspection departments such as motor manufacturers, and bearing vibration analysis by colleges and scientific research institutions.

Measuring principles of measuring instruments

The end face of the inner ring of the tested bearing is close to the shoulder of the main shaft and rotates at a constant specified speed. The outer ring does not rotate and bears a certain radial or axial load. The sensor probe is used to capture the center section of the raceway and the outer cylindrical surface of the outer ring The vibration (velocity) component of the outer ring of the bearing on the intersecting line, the radial vibration (velocity) component is converted into an electrical signal, and the electrical signal is input into the measurement amplification system for signal processing, and the average of the radial vibration velocity of the bearing in the low, medium and high frequency bands is displayed synchronously. root value

feature

The speed sensor is used to measure the 3-band speed value, P\/R setting control and defect pulse number setting control. The test bearing type: deep groove ball bearing, single-sided angular contact ball bearing.

Bearing noise test

Abnormal noise of bearings is part of bearing noise. It refers to various unpleasant sounds superimposed on the basic noise of bearings. There are many types of abnormal noises of bearings, and there are many reasons for them, such as rolling surface bumping, impurities entering the rolling surface, and guide rail surface matching. Bad, cage vibration, cage and steel ball collision, etc., there is currently no standard bearing abnormal sound detection method and procedure. However, from the perspective of bearing vibration waveform, there is no abnormal sound and low noise bearing waveform without fluctuating peak pulse .When the peak value of the pulse is large, unpleasant sound can be heard, which is usually called abnormal sound. The Bant series bearing abnormal sound measuring instrument is based on this principle to quantitatively measure the level of bearing abnormal sound