Application of eddy current detection in flaw detection of bearing parts

In the actual manufacturing process of bearing parts such as rings and rollers, defects such as cracks and sand spots will occur due to inherent cracks, folds, scratches, scales, rust, heat treatment, grinding and other factors, which not only affect the quality of the bearing quality, it also accelerates the damage during use and shortens the service life. Therefore, detecting the defects of these cracks and sand spots has become an important part of controlling product quality.

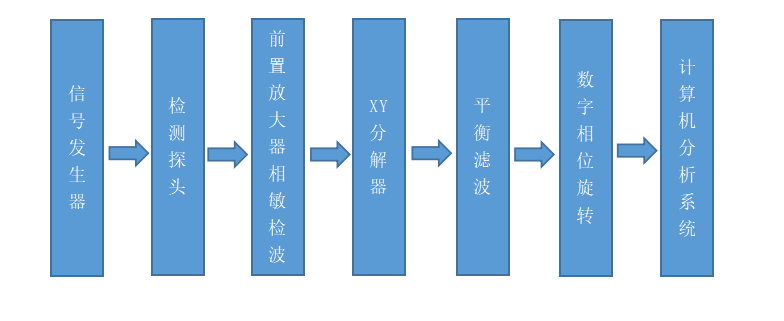

The basic principle of eddy current testing is that when a detection coil carrying an alternating current with a frequency is placed on a conductive test piece, an eddy current will be induced on the test piece, resulting in changes in the resistance and inductance of the detection coil impedance. Using impedance plane display technology To display the size information of the defect. The specific working principle is shown in the figure below.

The entire detection and analysis system is equipped with an automatic transmission sorting device, which can quickly and effectively complete the detection and sorting of related products. The system is used in the detection of bearing parts, and the bearing rollers and rings are detected separately, and batch detection The results show that the sensitivity of flaw detection equipment>0.03mm deep![]() The length is 1mm, the detection accuracy rate reaches 100%, and the detection speed is 0.7S per piece. The detection effect meets the needs of production.

The length is 1mm, the detection accuracy rate reaches 100%, and the detection speed is 0.7S per piece. The detection effect meets the needs of production.

Eddy current testing has many advantages such as fast detection speed, high accuracy, high degree of automation, and low cost. It has become a trend to gradually replace traditional manual inspection and magnetic particle inspection. It is believed that through continuous improvement and perfection, eddy current inspection technology will definitely serve better and production.