Introduction to the relevant principles of magnetoelectric inductive sensors

Magnetic inductionsensorAlso known as electrodynamic sensors, it has been widely and long-term used in the measurement of vibration speed, speed, and torque. The frequency response of common magnetoelectric vibration sensors is only tens of Hz to 2KHz. However, the internationally recognized bearing vibration detection The frequency range is 50Hz-10KHz, so it must be improved and innovated to meet the requirements of bearing vibration detection.

The electromagnetic induction sensor used in the BVT-1 bearing vibration measuring instrument developed by Hangzhou Bearing Test and Research Center in the mid-1980s is a relatively successful case developed at home and abroad. The following will introduce its working principle, key technology and design points .

1. Structure and principle

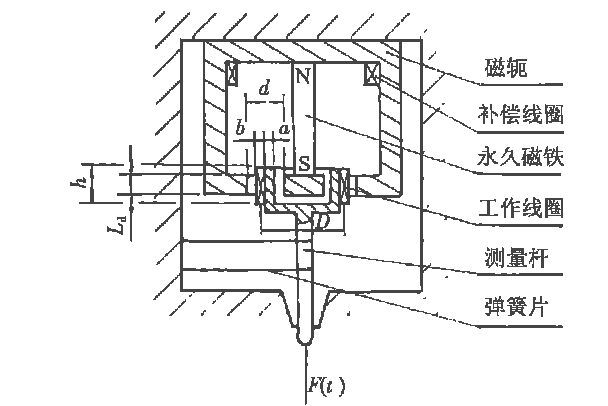

The structure of the magnetic induction sensor for bearing vibration measurement is shown in the figure below.

Its working principle is as follows:

The permanent magnet forms a constant flux magnetic circuit through the yoke. The working coil wound on the rigid measuring rod is located in the magnetic air gap of the magnetic circuit. The measuring rod is in rigid contact with the outer ring of the bearing under test. When the bearing under test is in the test state , the radial vibration velocity of the outer ring is directly transmitted to the rigid measuring rod, so that the measuring rod produces the same radial vibration velocity as the contact point of the outer ring of the bearing under test, and the working coil in the air gap of the magnetic circuit can obtain the bearing radial vibration velocity V Cutting the lines of magnetic force produces a magnetically induced electromotive force proportional to the vibration velocity V.

2. Reference papers on other important parameters (equations of motion of the measuring rod, calculation of pre-tightening force, and critical frequency) and design of main components (selection of working air gap, design of coil components), etc. The application in vibration measurement is greater than that of Zhang Genyuan and Chen Fanghua.

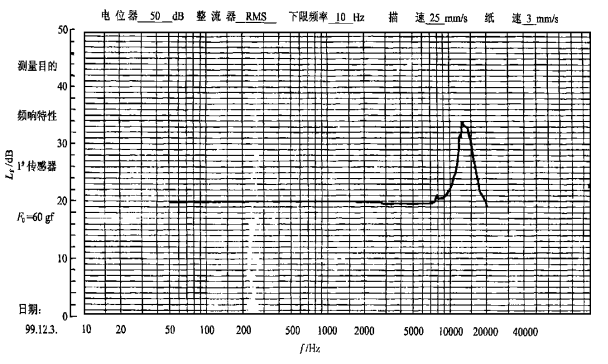

3. The frequency response of the sensor is shown in the figure below (to meet the measurement requirements of relevant national standards).

4. Summary

The improved magnetoelectric induction sensor can well meet the needs of bearing vibration measurement, meet the requirements of the national standard for bearing production inspection, and play an important role in actual production inspection. The birth of high frequency response magnetoelectric induction sensor has benefited Due to the emergence of new materials with high magnetic energy and reasonable structural design. The application in bearing vibration measurement is only a branch of its wide application field. Due to its excellent dynamic characteristics, it will be more widely used in the dynamic signal pickup. application.

The content of this article refers to the application of magnetoelectric induction sensors in bearing vibration measurement. Zhang Yuangen, Chen Fanghua. If there is any infringement, please contact us to delete it.